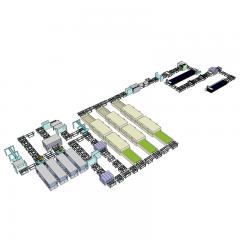

50MW Solar Module Production Line Solution

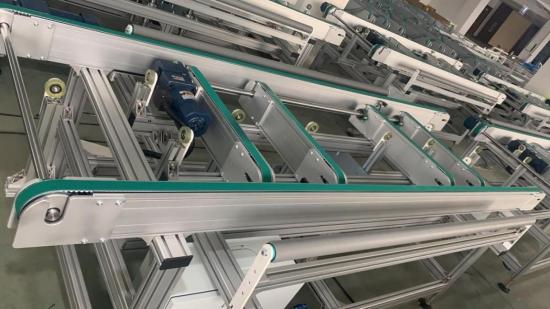

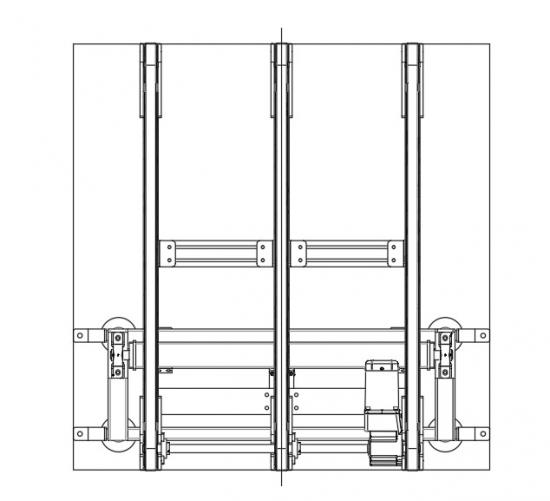

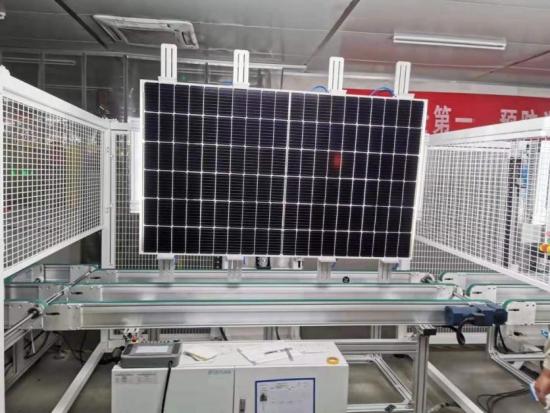

Our planning for the 50MW solar module production line is structured around seven core dimensions: product design, production line machinery, auxiliary equipment, facility scale, primary raw material procurement, main workshop layout, and facility requirements