1、 Product proposal

Based on the current market capacity and demand, taking a project with a construction scale of 50MW/year as an example, the series specifications for producing solar cell modules are 100-550W. The specific series specifications can be adjusted according to market demand. Different market capacities and demand forecasts result in different product solutions.

2、 Production line equipment

1. Automatic solar cell sorting instrument (1 unit): used for testing the detection and sorting of solar cells. Multi gear automatic sorting.

2. Fiber laser slicing machine (1 unit): used for cutting monocrystalline silicon and polycrystalline silicon solar cells.

3. Cutting machine (1 unit): used for cutting materials such as EVA/TPT.

4. String welding machine (2 units): Weld the front of the battery cells into a battery string.

5. Typesetting machine (1 unit): Arrange battery strings into components.

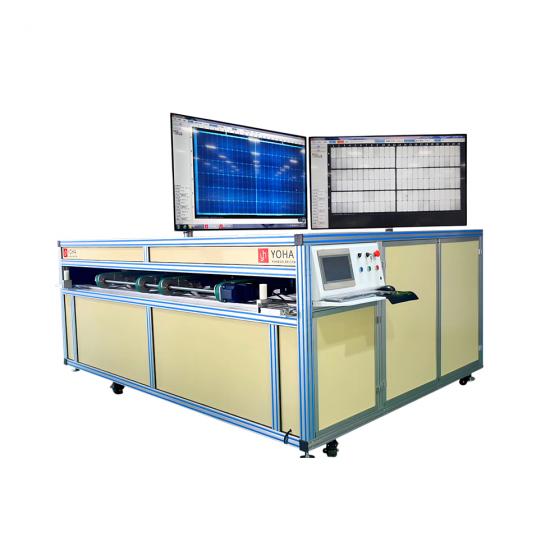

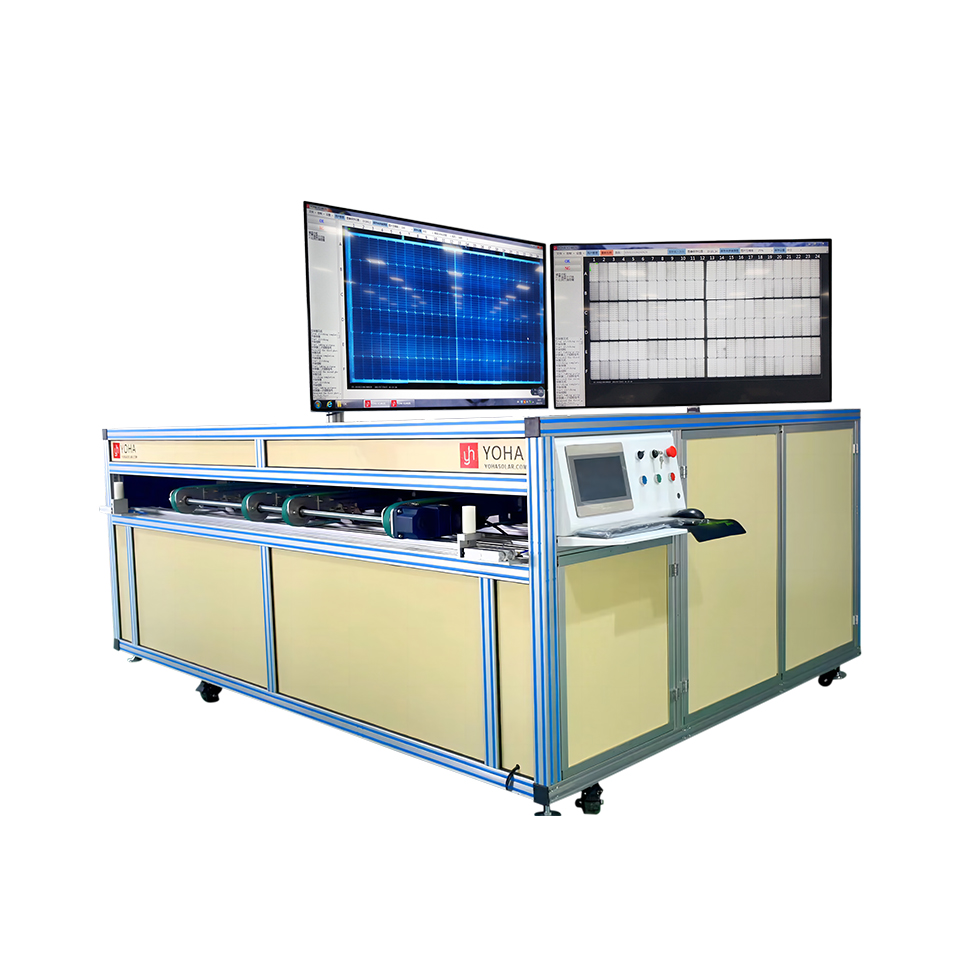

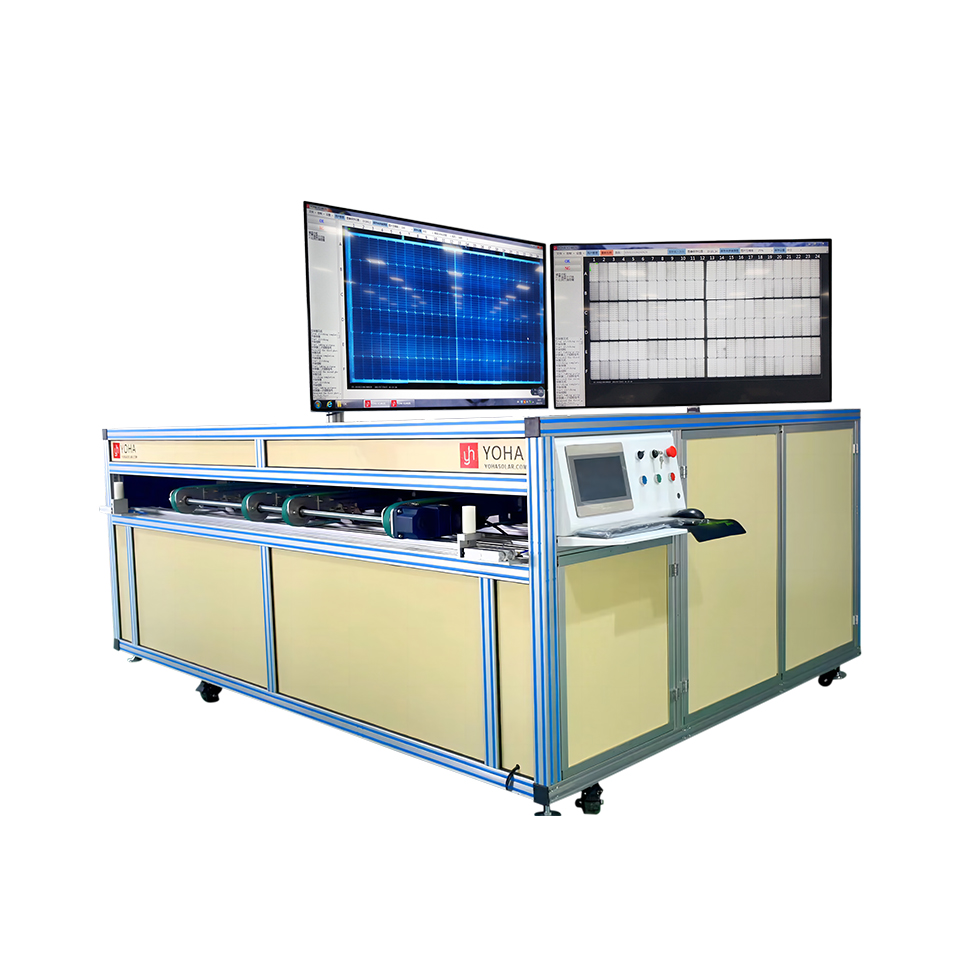

6. Pre lamination EL appearance defect detector (1 unit): used to detect EL and appearance defects of components before lamination. It can facilitate early detection of problems and reduce production costs.

7. Fully automatic laminating machine (1 unit): used for laminating photovoltaic modules, achieving automatic loading and unloading.

8. Framing machine: used for component framing processing.

9. Component IV tester: used to test component power and grading.

10. EL defect detector: used for final product defect detection.

3、 Auxiliary equipment

a. Trimming table (1 unit): After lamination, remove excess glue from the components.

b. Welding auxiliary station for junction box (1 unit): Welding junction box.

c. Turnover vehicles (6 units): used for turnover components.

d. Maintenance workbench (1 unit): used to detect faulty components for repair.

4、 Construction scale

The required production plant area varies depending on the output requirements of photovoltaic modules. In general, the construction requirements for production plants are:

a. Except for special requirements, the lighting, temperature, humidity, atmospheric pressure, and ventilation and emission facilities inside the factory should be able to meet the requirements of general electronic product assembly factories.

b. The solar module production line should generally be a clean workshop, with a room temperature of 25 ° C-30 ° C.

c. The room temperature of the component testing station is 25 ° C; According to the above requirements and the needs of each process, the construction of factories includes: raw material warehouse, preparation workshop, component packaging line (clean factory), component maintenance line (clean factory), finished product warehouse, etc.

5、 Main raw material supply

The main raw materials required for the production of this project each year are roughly shown in the table below: 1. Battery cells; 2. Glass; 3. Metal guide belt; 4. The principal is jointly and severally related; 5. EVA; 6. TPT; 7. Aluminum; 8. Junction box; 9. Sealing tape; 10. Sealant.

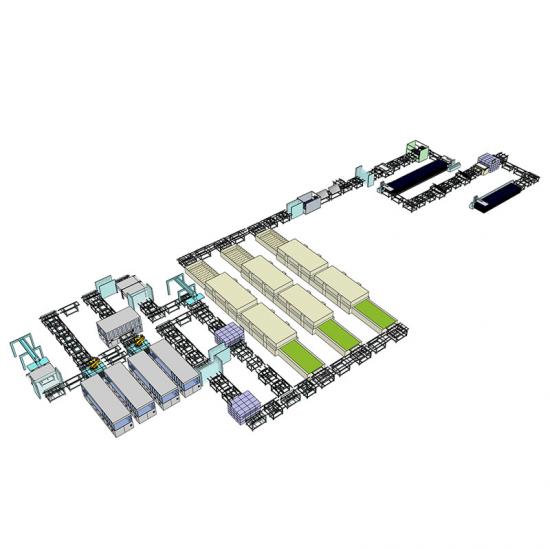

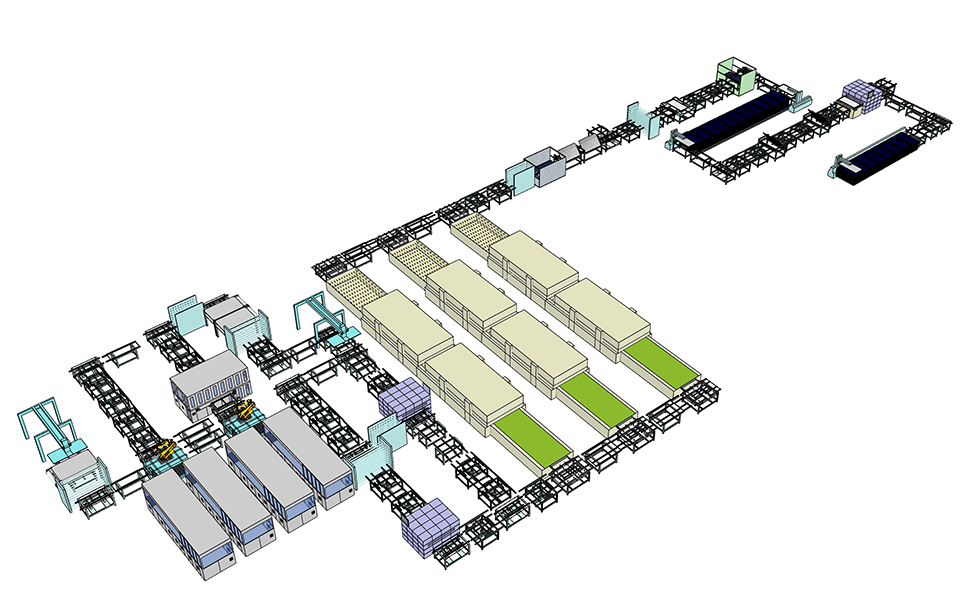

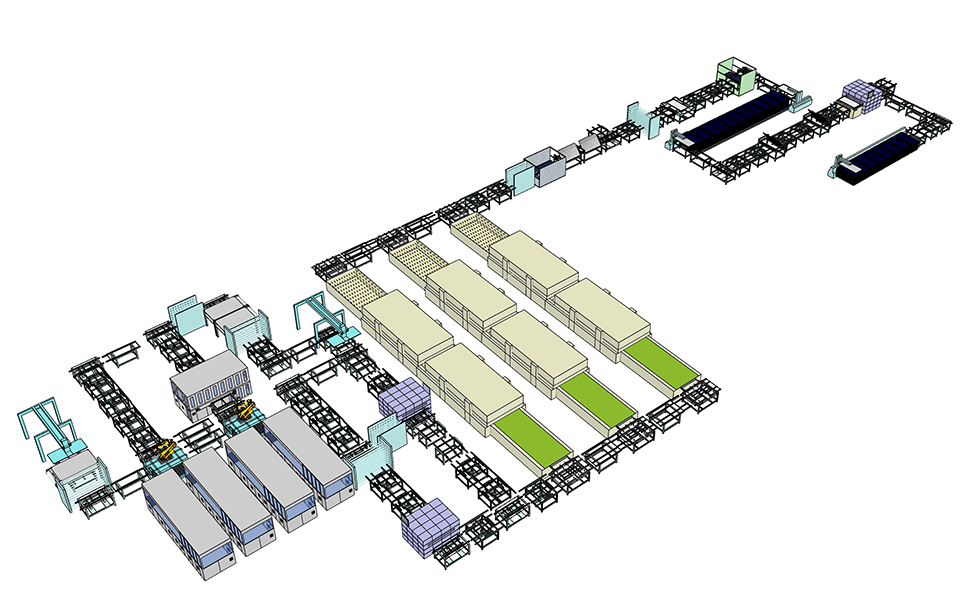

6、 Main production workshop layout plan

A general venue requires 4000 square meters and a constant temperature of 25 degrees Celsius throughout the year.

a. Raw material warehouse: Indoor cleanliness and hygiene are required, and items are placed on shelves. Storage items: welding tape, white glass, backing paper, Teflon high-temperature cloth, laminated rubber plate, rubber strip, aluminum alloy profile, silicone, cardboard box, packaging tape, wooden tray, etc.

b. Storage room for battery cells and EVA film: indoor cleanliness and dryness are required, and air conditioning is preferred if conditions permit.

c. Production workshop: used for component packaging production. Require indoor cleanliness and hygiene, and maintain a constant temperature.

d. Finished product warehouse: used for storing finished product components.